VISCOSE FILAMENT YARNS FROM ENKA

We produce viscose filament yarns in our own manufacturing process.

ENKA uses wood pulp from FSC®certified forestry. The cellulose is dissolved in a chemical process and spun out and wound up as a continuous filament yarn.

Applications of ENKA® Viscose

Product Range

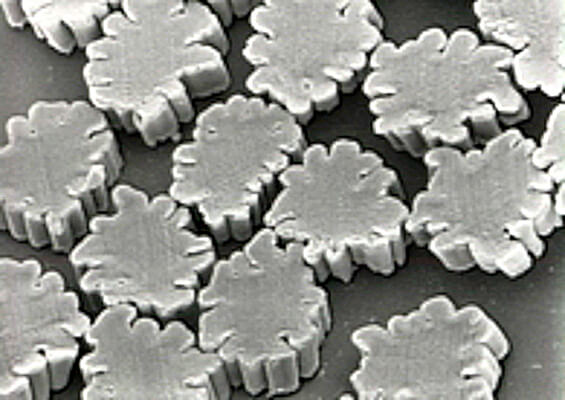

Our product portfolio includes viscose filament yarns with varying titre, filament count, tenacity, cross-section and lustre. ENKA® Viscose is available in yarn counts from 33 dtex to 330 dtex in gloss and deep dull for the various applications.

For more information on our product range, please visit info@enka.de.

example

ENKA'S FINEST YARN

ENKA’s finest viscose filament yarn (33 dtex f 24) weighs just 33 grams per 10 kilometres of yarn length, the individual filament only 1.375 grams per 10 kilometres.

Advantages of ENKA® viscose in the different areas of application

LINING

For decades, we have been a reliable partner to our discerning customers and work together with the leading European silk weavers in the production of high-quality linings.

The chemical purity and quality consistency of ENKA® viscose enables efficient further processing and dyeing.

Linings made of ENKA® viscose in clothing are comfortable to wear: due to the lack of electrostatic charge, the lining does not “stick, climb or creep” when being dressed, worn or undressed. In addition, ENKA® viscose has a climate-regulating effect due to its hygroscopic properties: the lining “cools” in summer and “warms” in winter.

Fashion

As an outer fabric, ENKA® viscose can show its silk-like character to full advantage in the fashion world, as a woven or knitted fabric – plain or also in blends with other yarns.

Technical and medical applications

Due to its properties as a filament yarn and its low static charge, ENKA® Viscose is suitable for use as technical velvet or in cleanroom applications.

The hygroscopic properties and its skin compatibility qualify ENKA® Viscose for use in the medical sector, e.g. for wound dressings.

And the chemical and thermal bonding properties of ENKA® viscose allow it to be used as a precursor yarn for the production of composites, e.g. when high heat resistance is required.